Now hiring Post Solder Assembler

Overview for Post Solder Assembler

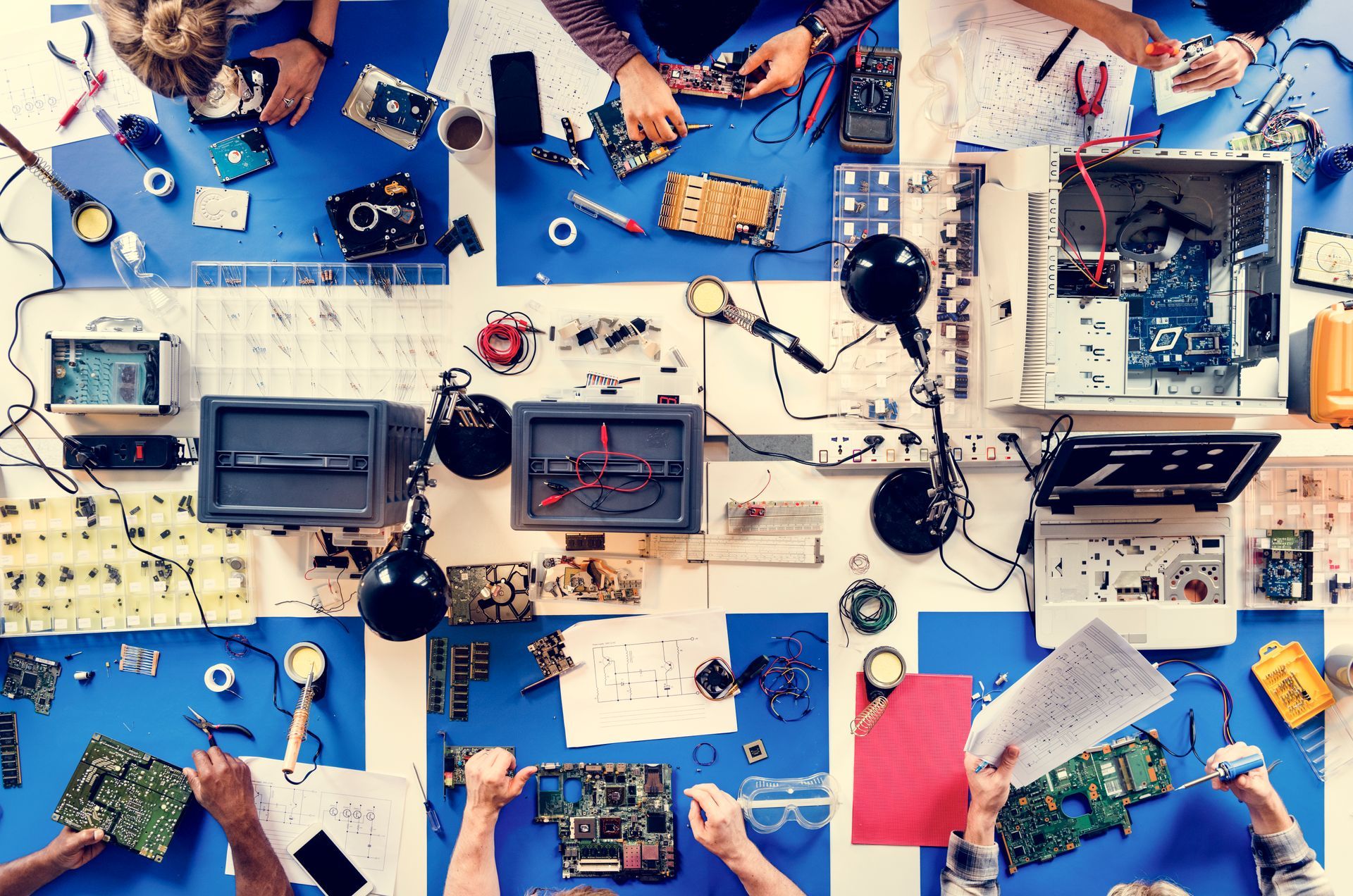

We are seeking a skilled Mechanical Assembler to join our dynamic team. In this role, you will be responsible for assembling mechanical components and systems with precision and attention to detail. The ideal candidate will possess a strong mechanical knowledge and experience with various assembly techniques, ensuring high-quality production standards are met. our corporation provides electronic manufacturing services (EMS) to multiple industries including aerospace, defense, and surveillance, automotive, pro-audio, medical and industrial controls

We are seeking candidates for our Post Solder Assembler position to add to our top-notch, talented team of quality professionals.

Required education, experience and attributes for Post Solder Assembler for a successful candidate are:

- Must have previous experience in a contract manufacturing or OEM environment.

- Education Level – High School.

- Minimum 5 years experience in solder assembler electronics manufacturing.

- Experience working in an ISO 9001 or AS9100-certified electronics-manufacturing environment.

- Must be proficient in English including the ability to communicate with all departments in the company.

- Basic understanding of IPC 610 Class 3 Standards for soldering through hole components such as switches, connectors, IC’, resistors etc. to PCB’s, lead trimming requirements, cleaning of PCB assemblies prior to final inspections process.

- Experienced with J-STD-001 and IPC 610 processes.

- Knowledge of military and or commercial electronics and components

- Able to read and interpret customer’s datasheets, blueprints and special instructions to install the wiring of cables, subassemblies, hardware and components to the printed circuit board or sub-assembly

Responsibilities for Post Solder Assembler:

- Soldering operations related to post solder operations on printed circuit boards, through hole and SMT components, cable and wire harness assemblies

- Knowledge of fluxes, solder wires, cleaning solvents, different processes (lead and lead free) fluxes.

- Understanding of IPC 610 Class 3 Standards for soldering SMT devices to PCB’s under the microscope: resistors, capacitors, diodes, SOIC’s, SOM’s, SOL’s, PLCC’s etc.

- Knowledge of soldering, routing and attaching (using adhesive) of jumpers wires to PCB’s.

- Understanding of simple diagrams, ECN’s or related documents to incorporate changes or modifications to PCB’s during the post solder assembly process.

- Knowledge of resistors color code and capacitors value reading, necessary to incorporate a change or a missing part to PCB’s.

- Knowledge of different electrical and manual tools such as electrical screw- driver, heat guns and torque driver.

- Complete understanding of PCB assembly drawings and related documents: ECN’s, assembly instructions, basic schematic reading.

- Understands and maintains a time standard time consistently in order to achieve a production schedule.

- Complete understanding of PCB assembly processes, component installation sequence of through hole components.

- Capable of using microscope to solder SMT devices such as QFP’s, jumpers to SMT parts per ECN’s, Capable of removing SMT devices using the PACE hot air rework station without causing damages to pads on PCB’s or components.

- Excellent touch-up soldering skills (SMT and TH) to perform post solder inspection functions.

- Proficient with microscopes.